1.The auxiliary line value ____ as we move towards higher concentrations in an enthalpy concentration diagram.

a) Increases

b) Decreases

c) Remains same

d) Exponentially increases

Explanation:The auxiliary line connects the boiling line and dew line by acting as a vertex of a right angle triangle with the hypotenuse as the isothermal line.

2. In an enthalpy concentration diagram, the point of intersection of a particular isothermal line to the Dew line is used to calculate _____________

a) Vapour phase composition

b) Liquid phase composition

c) Water mole fraction

d) Liquid phase weight fraction

Explanation:If we move along the isothermal line to the Dew Line and pin the intersection point, now we move vertically down to the composition value which is the required mole fraction in the vapour phase.

3. When we take a point between the Boiling line and the dew line in an enthalpy concentration diagram, then the mixture can exist in _______ in that particular point.

a) Liquid phase

b) Solid state

c) Gaseous state

d) Liquid and gas both

Explanation:The region of space between the Boiling line and the Dew line in an enthalpy concentration diagram exists in two phases which is the liquid phase and the gas phase. The liquid is dominant in the boiling line and gas in the dew line.

4. When we take a point between the Boiling line and the freezing line in an enthalpy concentration diagram, then the mixture can exist in _______ in that particular point.

a) Liquid phase

b) Solid state

c) Gaseous state

d) Liquid and gas both

Explanation:The region of space between the Boiling line and the freezing line in an enthalpy concentration diagram exists in single phase which is the liquid phase.

5. What do we mean by types of feeding in an evaporator?

a) Total number of different types of feed available

b) Types of steam temperature applied

c) Types of recycle feed applied

d) Types of product extracted

Explanation: The statement of types of feed in evaporator defines the way of arranging the recycle feed from one evaporator to two or more other evaporators is known as a type of feed.

6. Which one of the following is not a type of feeding in an evaporator?

a) Forward feed

b) Backward feed

c) Convoluted feed

d) Mixed feed

Explanation: There are four types of feed which are currently in industrial use which are –

- Forward feed

- Backward feed

- Parallel feed

- Mixed feed.

7.Parallel feed is almost the same as forward feed in an evaporator.

a) True

b) False

Explanation: No, the statement is wrong. In forward feed the feed is taken in series where the product of a particular single effect is the feed to the other, whereas the parallel feed setup has independent feed supply to each unit.

8. Why do we use more than one type of feeding in an evaporator?

a) To increase the feed efficiency

b) To increase the efficiency of the steam used

c) To decrease the steam consumption per unit mass of feed

d) To increase the steam consumption per unit mass of feed

Explanation:The steam consumption can be reduced to a low value if we use evaporators in series as it would then reuse the vapour from the first one to heat the second one, hence considerable reducing the consumption.

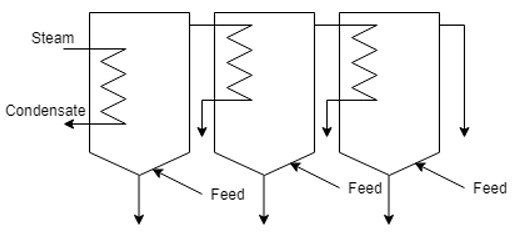

9. What is the name of the following evaporator? Recognize the type of feed.

a) Forward feed

b) Backward feed

c) Parallel feed

d) Mixed feed

Explanation: The feed supply arrangement is independent of the product of others, that is the feed being given to the first evaporator is not the product from 2nd evaporator and vice versa rather separate for each. Hence it is called a Parallel feed multiple effect evaporator

10. The product concentration in a forward feed evaporator _________ as we move to successive evaporators.

a) Increases

b) Decreases

c) Remains same

d) Is different for each

Explanation: The forward feed setup has series connection where the product of a particular single effect is the feed to the other. Hence the product concentration increases with each subsequent evaporator